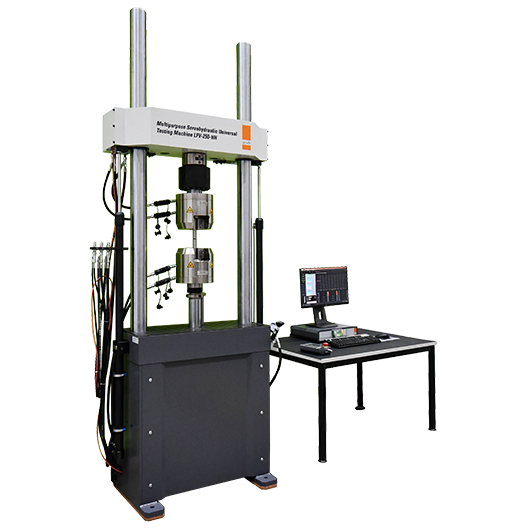

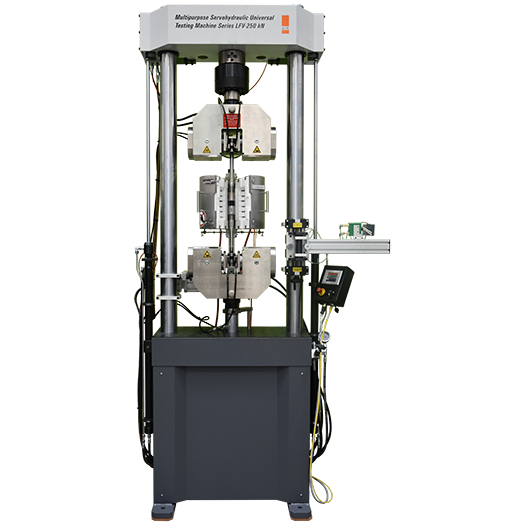

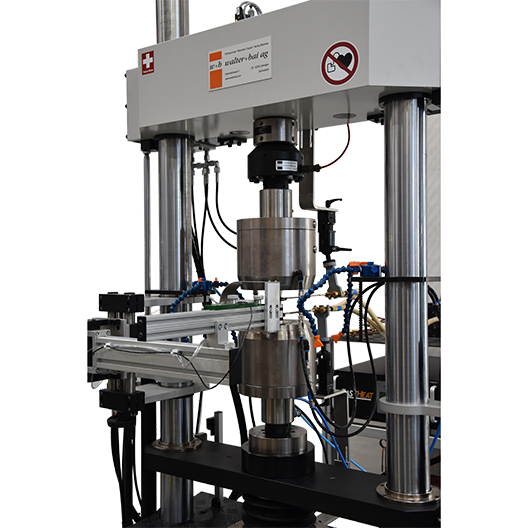

Servohydraulic Multipurpose Fatigue Test System Floor Standing with Actuator in lower base Series LFV up to 630 kN

Owing to over 45 years of experience in the production of a wide range of dynamic and fatigue servohydraulic testing system in different force capacities and configurations meeting the requirements of quality control, production, product research and development our machines include a numerous of features and achievements guaranteeing operational efficiency, safety and reliable testing with minimum down-time.

All LFV servohydraulic systems integrates reliable w+b servo-controlled hydraulic actuation with high-resolution & high-speed digital closed loop controls, a broad portfolio of complement accessories and comprehensive Dion7 application software packages making these systems the suitable across the full spectrum of static and dynamic testing including:

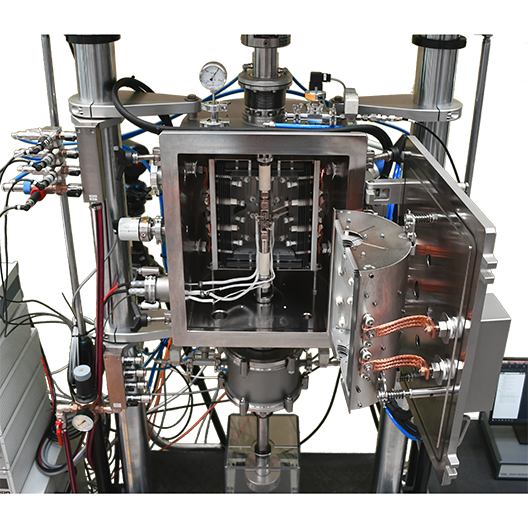

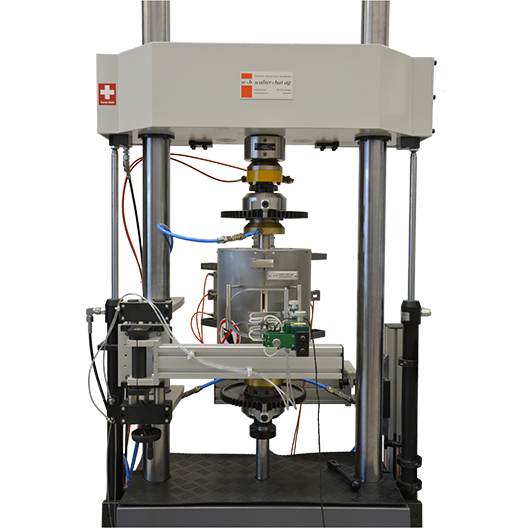

Tension • Bending • High Cycle Fatigue • Fracture Toughness • Crack Propagation • Environmental Testing • Component Durability • Compression • Thermo Mechanical Fatigue (TMF) • Low Cycle Fatigue (LCF) • Fatigue Crack Growth • K1C / J1C • Stress and Strain Relaxation • Component Strength

Key Features

- Latest digital control electronics with closed loop control and high data acquisition rate, and self-identification transducer coding

- Rigid machine frame with high stiffness, provides superior axial and lateral stiffness and guarantees robust, durable, and long-term operation

- Increased stiffness means higher efficiency, as the amount of energy needed to overcome the frame deformation in each loading cycle is less

- To increase the stiffness, appropriate column diameter and rigid crosshead with base platen are provided, this results in increased weight of load frame, which in turn improves the natural frequency of the load frame and reduces vibration delivered to laboratory floor / building.

- Test space adjustment available by mechanical and automatic lifting systems

- Hydraulic passive clamping (Version HH) system assures that the upper crosshead is clamped to columns without applying any hydraulic pressure

- Accurate & parallel upper crosshead movement for improved alignment (elimination of machine's bending strain in the sample).

- Double acting and double ended equal area servo actuator with hydrostatic 4-pocket bearings for the best friction-free static and dynamic performance, with virtually service-free operation.

- Highly accurate load cell and digital displacement transducer

- High-performance servovalve(s)

- Enhanced safety features for best protection of operator during testing

- Alignment fixtures with related alignment verification equipment

- Ergonomic design