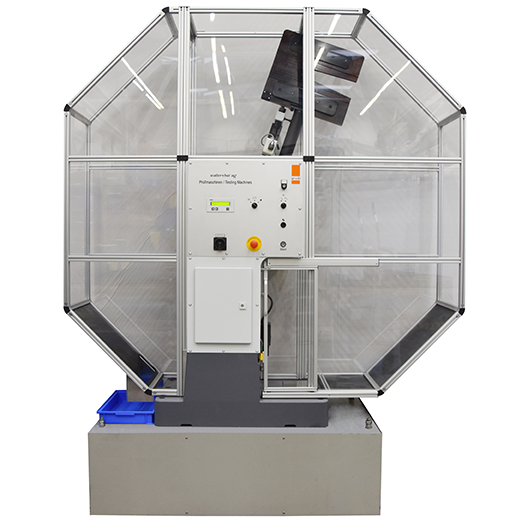

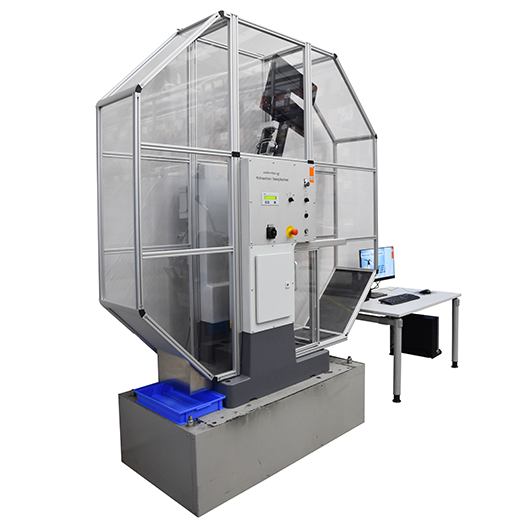

PH Version CHV Expandable Pedelum Impact Tester up to 900 Joule

with instrumented strain gauged striking edge with high speed data acquisition system, patented laser opto-electronic-measuring-system for deflection (bending) and crack opening measurement for the experimental determination of the intensity of stress, KID/KIC-factor with

ultra-high speed ADC board for data acquisition or robot for fully automatic testing in combination with pre-conditioning chambers or without.

The Impact Testers confirm to international standards as ISO 148-1 & ASTM E23 and are suitable for impact bending tests to CHARPY and with accessories to IZOD, Impact Tensile & Brugger tests as well as for sub-sized & DVMK specimens.

The impact tester is composed of a sturdy, vibration-damping steel cast iron metallic frame with high stiffness on a lower massive structure able to ensure a steady base.

The unit is designed as symmetric U-Frame and provides easy excess for sample loading.

Ergonomically integrated digital display and operating elements for status and error messages.

Simple, fast and safe operation provided through slid able front door, easy sample centring and safe release button(s). The pendulum is automatically returned after it swung back close to its release position to safe time. Optionally automatic pendulum release mode is available when door is closed preferable ordered when tests according to ISO 148 or ASTM E23 on temperature conditioned specimens are performed which must be tested within 5 seconds since removing them from the temperature unit.

The unit can be changed rapidly from one energy range to another.

The unit can be operated as stand-alone unit with safe two hand operation or in connection with DIONIMPACT application software package.

Safety guard with acryl-glass with safety interlock-switch according to the safety regulations.

Small slidable front door for convenient sample insert and right / left side can be hinged open for easy access to change impact hammer, clean the unit, maintenance work or inspection and calibration works. The unit confirms the requirements of EC Machinery Directive 2006/42/EC and EN ISO 12100 and EN ISO 13849-1/2