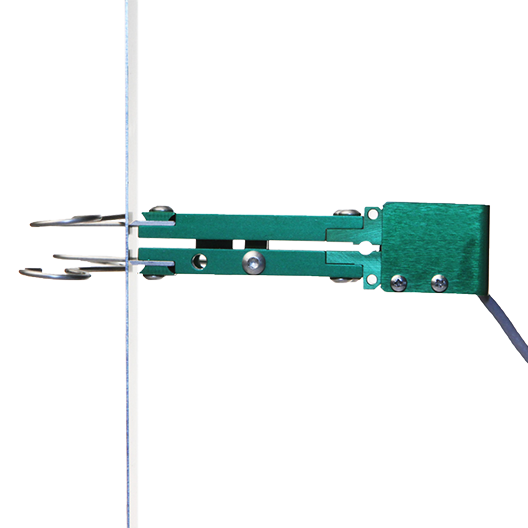

Miniature Axial Extensometers Series 3442

Gauge lengths are available from 3 mm to 50 mm and full-scale measuring ranges from ±0.5 mm to +12.5 mm.

Model 3442 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers.

Features

-

May be left on through specimen failure

-

All standard units meet existing ISO 9513, class 0,5 and ASTM class B-1 requirements for gauge lengths ≥6 mm and class 1 according to ISO 9513 and ASTM class B-2 for ≤5 mm accuracy.

-

All models can measure in both tension and compression and can be used for cyclic testing.

-

Gauge length pin helps set gauge length accurately for all gauge length configurations.

-

Full bridge, 350 ohm strain gauged design

-

Mechanical overtravel stops in both directions.

-

Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

-

Gauge length adapter kits enable configuration of multiple gauge lengths with one extensometer.

-

Replaceable arms and spacers for ease of repair.

-

Hardened tool steel knife edges are easily replaced

-

High and low temperature options extend operation from as low as -265 °C to +200 °C

-

Replaceable arms and spacers for ease of repair. This also allows changing the gage length for different test requirements

-

Includes high quality foam lined case