LFM Electromechanical Floor Standing Machines 600 to 2500 kN

These rugged and durable 6-column Systems are designed for high capacity and high strength Materials Testing.

Typical application for this high force systems includes testing of metals and alloys, fasteners, bolts, plate steels, advanced composites and Civil-, Aerospace-, Automotive-, Rails or Marine structures and components.

Key Features

- Rigid 6-column machine frame with high stiffness providing superior axial and lateral stiffness and guarantees robust, durable and long-term operation

- High machine stiffness and appropriate machine mass reduces shock at sample failure and provides smooth breaking

- Two high resolution ball screws driven with pre-stressed ball nuts and low backlash reducing gear system provides high load capacity and high mechanical resolution

- Spindle with flange double-nut, sealed and greased for long maintenance intervals

- Spindle, flange double-nut and ball-screw shaft grinded pairwise for reduced pitch error

- Controlled by a brush-less high responsive, maintenance-free and low noise AC servomotor to drive the mobile traverse guarantees positioning accuracy and repeatability

- AC servomotor provides continuous high test speed up to nominal force for continuous operation

- Ball Screws (spindles) protection over full travel through oil- and moisture-resistant, sealed bellows made from polyester fabric, coated with polyurethane inside and out side

- Additional four (4) hardened and chromium plated guiding columns for increased lateral stiffness

- Adjustable end-stops in both (UP/DOWN) directions for the best protection of operator, test sample and machine

- End stops for maximum travel protection

- One-point spindle lubrication

Precision strain gauge load cell mounted on (movable) crosshead - Alignment fixtures mounted between crosshead and load cell with related alignment verification equipment optionally available

- Electrical cabinet with air-fan, complete power supply and control module, relays etc. mounted on rear side of machine’s base

- Emergency stop direct at the machine

- Durable structured coating (paint)

- Use of high quality components and assemblies of reputable companies

- Bolts for machine lifting

- Adjustable feet for leveling the testing machine

- The machine is free-standing on shock absorbers, requiring no special foundations

- Ergonomic working height

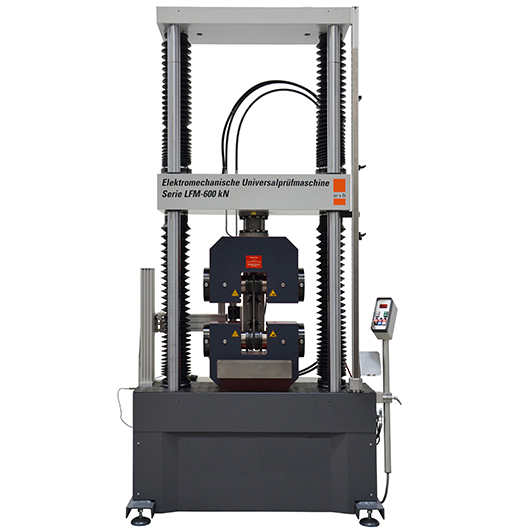

Electromechanical Universal Testing Machine LFM-600 kN with Non-Shift Grips

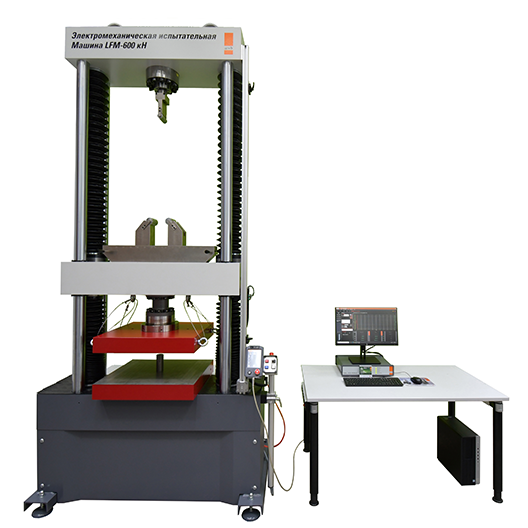

Electromechanical Universal Testing Machine LFM-600 kN with Parallel Grips

Electromechanical Universal Testing Machine LFM-1000 kN

Electromechanical Universal Testing Machine 1200 kN

Electromechanical Universal Testing Machine LFM-1600 kN

Bespoken Electromechanical Univeral Testing Machine LFM-2000 kN

2500 kN Hybrid Testing Machine

1200 kN Electromechanical Universal Testing Machine with two Side Test-Areas

Side Test Area System

Dual Test Space Electromechanical Universal Testing Machine

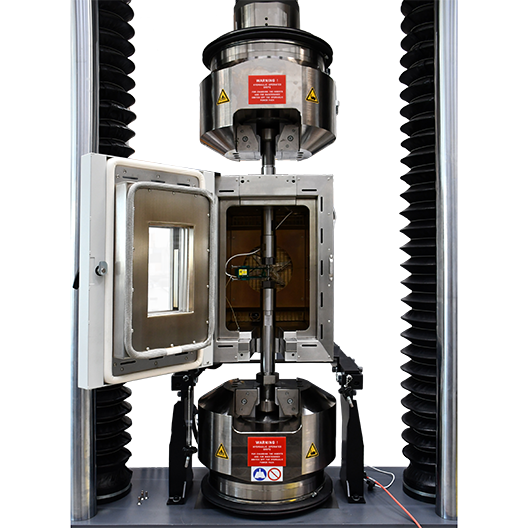

Electromechanical Universal Testing Machine with Environmental Chamber