General Purpose Axial Extensometer Series 3542

Gauge lengths are available from 10 mm to 80 mm (and 0.5 to 2 inches) and full-scale measuring ranges from 5% to 100% strain.

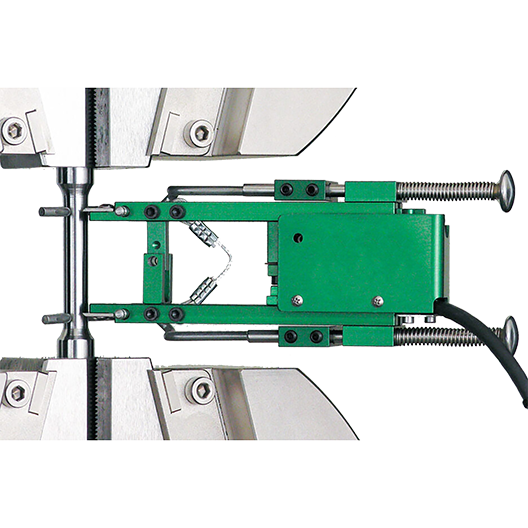

The dual flexure design makes them very rugged and insensitive to vibrations, which permits higher frequency operation.

They come standard with quick attach kit, making it possible to mount the extensometer on the test specimen quickly and easily with one hand. The quick attach kit can be removed, allowing mounting of the extensometer with springs or rubber bands. The Series 3542 extensometers are strain gauged devices.

Model 3542 extensometers are applicable for testing with the following standards:

- ISO 6892-1, 527-2, 527-4, 527-5, 10113

- ASTM E8, E9, D3039, D638, A370, D3552, E517, E646

The Model 3542 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. For gauge lengths less than 20 mm (0.8 inches), we recommend the more compact Model 3442.

For gauge lengths 100 mm (4 inches) or greater see Model 3542L.

Features:

-

May be left on through specimen failure

-

All standard units meet existing ISO 9513, class 0,5 and ASTM class B-1 requirements for accuracy.

-

Applicable for testing to:

-ISO 6892-1, ISO 527-2, ISO 527-4, ISO 527-5, ISO 10113

-ASTM E8, E9, D3039, D638, A370, D3552, E517, E646

-

All models can measure in both tension and compression and can be used for cyclic testing.

-

Full bridge, 350 ohm strain gauged design

-

Standard quick attach kit allows one hand mounting to specimens.

-

Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

-

All models have mechanical overtravel stops in both directions. Cable stops are used for overtravel protection where required. Epsilon's cable stops are fully contained between the arms of the extensometer and do not hang below where they can interfere with fixturing – especially during compression testing.

-

Hardened tool steel knife edges are easily replaced

-

Gauge length adapter kits enable configuration of multiple gauge lengths with one extensometer.

-

High and low temperature options extend operation from as low as -265 °C to +200 °C

-

Replaceable arms and spacers for ease of repair. This also allows changing the gage length for different test requirements

-

Includes high quality foam lined case